Isolamento Termico Superiore ed Efficienza Energetica

Come i pannelli sandwich riducono al minimo i ponti termici nelle strutture in acciaio

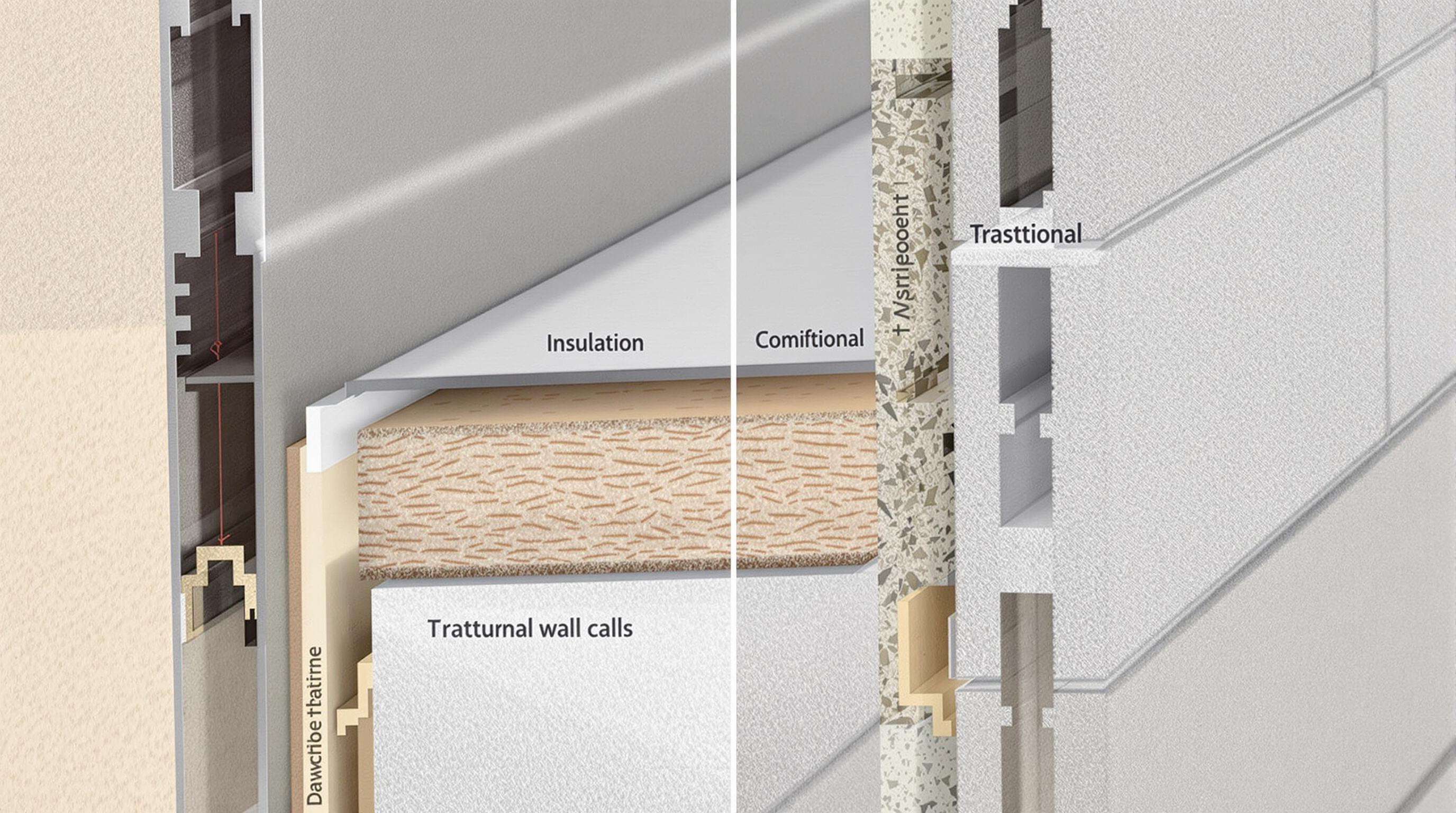

I capannoni in acciaio beneficiano dell'uso di pannelli sandwich perché, grazie al loro design con un nucleo isolante continuo tra i due strati metallici, prevengono il ponte termico. I metodi tradizionali di aggiunta separata dell'isolamento spesso comportano la formazione di spazi vuoti attorno alle viti e nei punti di connessione, mentre questi pannelli presentano nuclei in poliuretano (PU) o in lana minerale che vengono uniti tra loro durante il processo produttivo, creando di fatto una barriera termica solida e priva di interruzioni. Secondo una ricerca pubblicata nel 2011 da Al-Sanea e Zedan, questa tipologia di costruzione riduce il trasferimento di calore attraverso le strutture tra il 40% e il 60%, assicurando che l'energia preziosa non venga dispersa attraverso quelle criticità rappresentate dai punti di incontro tra le diverse parti dell'edificio.

Confronto dei valori R: pannelli sandwich contro materiali tradizionali per rivestimenti

| Materiale | Valore R per pollice | Spessore per R-20 |

|---|---|---|

| Pannello sandwich in PU | 6.5 | 3.1" |

| Pannello sandwich in EPS | 5.0 | 4.0" |

| Paramento in mattoni | 0.2 | 100" |

| Fibrocemento | 0.5 | 40" |

Secondo il Rapporto sui Materiali Isolanti 2023, i pannelli sandwich richiedono uno spessore del 75% inferiore rispetto ai materiali murari per raggiungere un valore R-20, riducendo significativamente l'ingombro delle pareti migliorando al contempo le prestazioni termiche.

Ruolo dei materiali del nucleo (PU, EPS, lana minerale) nelle prestazioni termiche a lungo termine

- Nuclei in PU : Forniscono il più alto valore iniziale di resistenza termica (6,5/pollice), ma subiscono una degradazione più rapida sotto prolungata esposizione ai raggi UV.

- Nuclei in EPS : Mantengono fino al 98% della loro efficienza termica in ambienti ad alta umidità (Kumar et al., 2020), risultando ideali per magazzini frigoriferi e climi umidi.

- Fabbricazione a partire da fibre sintetiche : Offrono un valore di isolamento leggermente inferiore rispetto al PU, ma mantengono nel tempo prestazioni stabili. Test sul campo mostrano che i pannelli in lana minerale mantengono valori U inferiori a 0,28 W/m²K dopo 15 anni in ambienti industriali, confermando la loro affidabilità a lungo termine.

Riduzione del carico degli impianti HVAC e dei costi operativi grazie a un'efficace isolamento termico

Minimizzando le fluttuazioni di temperatura, i pannelli sandwich riducono del 35% il tempo di funzionamento degli impianti HVAC nelle strutture a clima controllato come i magazzini ( Bergmann Becker et al., 2022 ). Nelle applicazioni di stoccaggio refrigerato, ciò si traduce in risparmi energetici annuali compresi tra 0,0 e 12,0 dollari per piede quadrato, con risparmi che variano da 0,18 a 0,25 dollari per piede quadrato. I tempi tipici di ritorno dell'investimento si aggirano intorno ai quattro anni per le strutture commerciali in acciaio.

Integrazione senza soluzione di continuità e installazione rapida nelle costruzioni in acciaio

Compatibilità dei pannelli sandwich con i sistemi di intelaiatura in acciaio

I pannelli sandwich possono effettivamente essere modellati in curve molto strette, a volte con un raggio ridotto fino a un metro, senza compromettere la loro efficienza energetica o le prestazioni strutturali. Funzionano bene con strutture in acciaio grazie alle simili proprietà di espansione termica tra gli strati del pannello e i componenti in acciaio. I collegamenti sono sottoposti a minore stress rispetto a quelli che coinvolgono materiali misti, il che aiuta a evitare guasti alle giunzioni.

Installazione Rapida e Tempi di Costruzione Ridotti

Le strutture con telaio in acciaio abbinate a pannelli sandwich richiedono meno ore di manodopera rispetto alla muratura tradizionale, poiché il loro metodo di assemblaggio a secco rende l'installazione molto più veloce. Per impianti produttivi, una squadra di operai può coprire fino a 400 metri quadrati di superficie al giorno, riducendo i tempi totali del progetto del 30% e abbattendo notevolmente i costi associati. I materiali da costruzione leggeri rendono ancora più facile il trasporto di grandi sezioni precostituite e il loro rapido montaggio in cantiere.

Flessibilità Progettuale per Strutture Modulari, Curve e Prefabbricate

La flessibilità offerta dalle piastre sandwich consente di integrarle facilmente in curve strette con raggi ridotti fino a 3 metri senza compromettere le prestazioni. Per applicazioni strutturali modulari, le piastre vengono prodotte fino a una lunghezza di 12 metri, massimizzando l'efficienza logistica. Le riparazioni possono essere eseguite rapidamente, poiché le piastre composite possono generalmente essere riparate in meno della metà del tempo necessario per ricostruire pareti standard utilizzando materiali tradizionali.

Elevata Resistenza Strutturale e Durata nel Tempo

Elevata Portata delle Piastre Sandwich

Le piastre sandwich sono progettate per sopportare carichi considerevoli con una capacità che può raggiungere fino a 35 kN/m², rendendole adatte alle moderne strutture in acciaio multipiano. Il metodo costruttivo distribuisce efficacemente lo sforzo attraverso le superfici metalliche e il materiale di riempimento del nucleo. Test effettuati dall'Istituto per la Sicurezza Edile nel 2023 hanno dimostrato come queste piastre siano in grado di assorbire circa il 92% dell'energia sismica simulata, dove i materiali convenzionali hanno mostrato carenze.

Resistenza alla Corrosione in Ambienti Industriali Severi

Dotati di avanzate verniciature in zinco-alluminio, i pannelli a sandwich superano nel tempo le prestazioni dei pannelli metallici standard. Studi condotti nel 2022 hanno riportato un tasso di corrosione di soli 0,05 mm in ambienti costieri, chimici o altri ambienti industriali noti per le condizioni severe. Mantenendo il substrato in acciaio protetto dagli agenti atmosferici e dalla possibile corrosione interna, questi pannelli migliorano la durata complessiva della struttura rispetto alle costruzioni tradizionali.

Resistenza agli Impatti delle Finiture Metalliche sulla Durabilità

I pannelli sandwich con faccia in acciaio presentano una forte resistenza agli urti, sopportando forze pari a circa 2,5 joule in presenza di macchinari pesanti comunemente utilizzati negli ambienti industriali. Le opzioni in alluminio offrono soluzioni più leggere, mantenendo un equilibrio con le esigenze di integrità strutturale. Durante i test antincendio, i pannelli compositi, anche con spessori minimi di acciaio, mostrano una notevole durata, conservando fino all'80% della resistenza meccanica dopo prolungata esposizione a temperature elevate, superando le prestazioni dei comuni pannelli isolanti che raggiungono circa il 52% in situazioni comparabili, garantendo così maggiori garanzie di sicurezza negli ambienti industriali.

Sezione FAQ

Quali sono i principali vantaggi nell'utilizzo di pannelli sandwich nelle costruzioni in acciaio?

I principali vantaggi nell'utilizzo di pannelli sandwich nelle strutture in acciaio includono un'ottima isolamento termico, efficienza energetica, riduzione del carico HVAC, elevata resistenza strutturale, durata nel tempo, compatibilità con i sistemi di intelaiatura in acciaio e tempi rapidi di installazione.

Come fanno i pannelli sandwich a ridurre il ponte termico?

I pannelli sandwich sono progettati con un nucleo isolante continuo posizionato tra due strati metallici, eliminando i punti di ponte termico. I nuclei realizzati in poliuretano (PU) o lana minerale creano barriere solide, riducendo il trasferimento di calore attraverso le strutture del 40% al 60% e mantenendo l'efficienza energetica.

Qual è la differenza negli indici R tra i pannelli sandwich e i materiali tradizionali per rivestimenti?

Gli indici R dei pannelli sandwich sono significativamente più elevati rispetto a quelli dei materiali tradizionali per rivestimenti, considerando lo spessore per pollice: i pannelli sandwich in PU hanno un indice R di 6,5, mentre il rivestimento in mattoni ha un indice R di 0,2 per pollice. Di conseguenza, i pannelli sandwich offrono un migliore isolamento termico con minor spessore.

Quali sono i materiali del nucleo dei pannelli sandwich e come influenzano le prestazioni?

I pannelli sandwich utilizzano materiali per il nucleo come poliuretano (PU), polistirene espanso (EPS) e lana minerale. Il PU fornisce il valore iniziale R più alto, seguito dall'EPS che mantiene l'efficienza termica sotto l'esposizione UV. La lana minerale è la più duratura con valori U stabili nel corso delle decadi.

Come contribuiscono i pannelli sandwich alla riduzione del carico termico e dei costi operativi?

I pannelli sandwich riducono al minimo le fluttuazioni di temperatura, riducendo di conseguenza il tempo di funzionamento degli impianti HVAC del 35% negli ambienti climatizzati. Nelle applicazioni per celle frigorifere, ciò comporta un risparmio annuale di energia pari a $0,18 - $0,25 al piede quadrato, con un tipico ritorno dell'investimento entro quattro anni.

Indice

-

Isolamento Termico Superiore ed Efficienza Energetica

- Come i pannelli sandwich riducono al minimo i ponti termici nelle strutture in acciaio

- Confronto dei valori R: pannelli sandwich contro materiali tradizionali per rivestimenti

- Ruolo dei materiali del nucleo (PU, EPS, lana minerale) nelle prestazioni termiche a lungo termine

- Riduzione del carico degli impianti HVAC e dei costi operativi grazie a un'efficace isolamento termico

- Integrazione senza soluzione di continuità e installazione rapida nelle costruzioni in acciaio

- Elevata Resistenza Strutturale e Durata nel Tempo

-

Sezione FAQ

- Quali sono i principali vantaggi nell'utilizzo di pannelli sandwich nelle costruzioni in acciaio?

- Come fanno i pannelli sandwich a ridurre il ponte termico?

- Qual è la differenza negli indici R tra i pannelli sandwich e i materiali tradizionali per rivestimenti?

- Quali sono i materiali del nucleo dei pannelli sandwich e come influenzano le prestazioni?

- Come contribuiscono i pannelli sandwich alla riduzione del carico termico e dei costi operativi?